Remember learning to ride a bike? Those first few wobbly attempts when you hadn’t yet developed muscle memory?

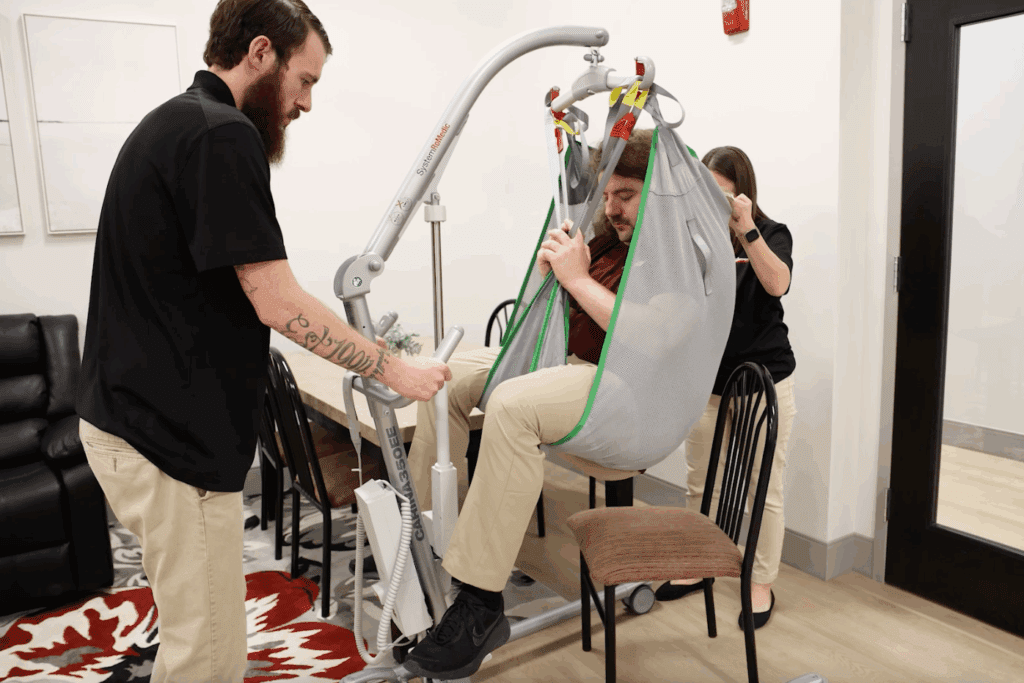

Now imagine, instead of a bicycle, you were learning to operate a patient lift in someone’s home, with a real person depending on you. For new Direct Support Professionals, that first ‘ride’ can be intimidating and potentially dangerous for both the employee and the client.

Addressing this type of new hire risk is critical for organizations like Emmaus. Here’s how Emmaus Homes, an MEM policyholder providing in-home disability support services, developed a creative solution to the challenge.

The high cost of learning on the job

The numbers paint a clear picture: 35% of workplace injuries involve employees in their first year on the job. This risk is even higher for organizations like Emmaus whose employees must learn to use specialized equipment in different home environments.

According to Sheila Schmidt, Safety and Risk Services Regional Manager at MEM, this trend persists for two reasons. “One is math,” she explained. “We have so much turnover and movement across so many industries that we’re just seeing more and more new hires than we have in the past. Also, we’re pushing those new hires out faster. They’re usually filling vacant spots, and we need them to hit the ground running.”

Without structured onboarding and training, new employees often have to figure things out as they go. However, safety procedures aren’t always common sense, and this approach can lead to serious, preventable injuries.

📍 Want to learn more about reducing the risk of new hire injuries with strategic onboarding? Listen to our podcast episode, New Hire Onboarding: Setting New Employees Up for Success.

The challenge: Creating consistency in variable environments

At Emmaus, leadership noticed a pattern: More than half of their workplace injuries involved new hires. More experienced team members trained new employees on the job, but this approach wasn’t consistent enough.

Providing support to clients in their homes creates a unique training challenge. Employees must navigate many different variables. Home layouts. Types of equipment. Unique client needs. Without being fully prepared for these varying environments, staff members were experiencing strains, sprains, and falls.

Emmaus recognized an opportunity to standardize training and improve their employee safety program – starting with these questions:

- What if new employees could practice in a risk-free environment?

- What if they could get comfortable with a variety of types of equipment before working with clients?

The answer, of course, was to give employees more hands-on training. Accomplishing this goal was easier said than done; it required a creative vision.

The solution: A realistic training environment

To turn their idea into reality, Emmaus developed a simulation lab that replicates their clients’ home environments. The adaptive equipment training lab includes:

- Actual lifts like those used in clients’ homes

- Real mobility equipment and assistive devices

- A realistic home layout with typical spacing constraints

- Common household furniture arrangements

The lab allows Direct Support Professionals to practice using equipment in a controlled setting that closely mimics what they’ll encounter on the job.

Andrew Grosch, Senior Safety and Risk Consultant at MEM, worked with Emmaus throughout the lab’s implementation.

“What stood out to me was the policyholder’s creativity,” recalled Grosch. “They didn’t wait for a solution; they created one. This adaptive equipment lab is a great way to provide new hires with thorough, systematic training.”

Emmaus built the lab out gradually over a few years as resources allowed. This phased approach made the project financially feasible while addressing their immediate safety needs. An MEM safety grant helped fund the lab, which became fully operational near the end of 2024. Going forward, the organization can add equipment as new needs arise.

“This training lab has really been a game changer,” reflected Tisha Greco, who oversees the safety grant application process. “Even in our safety world, work comp world, it never crossed any of our minds that this would be a great idea… We were thrilled when this application came in.”

Practice makes prepared: Expected impact on injuries and claims

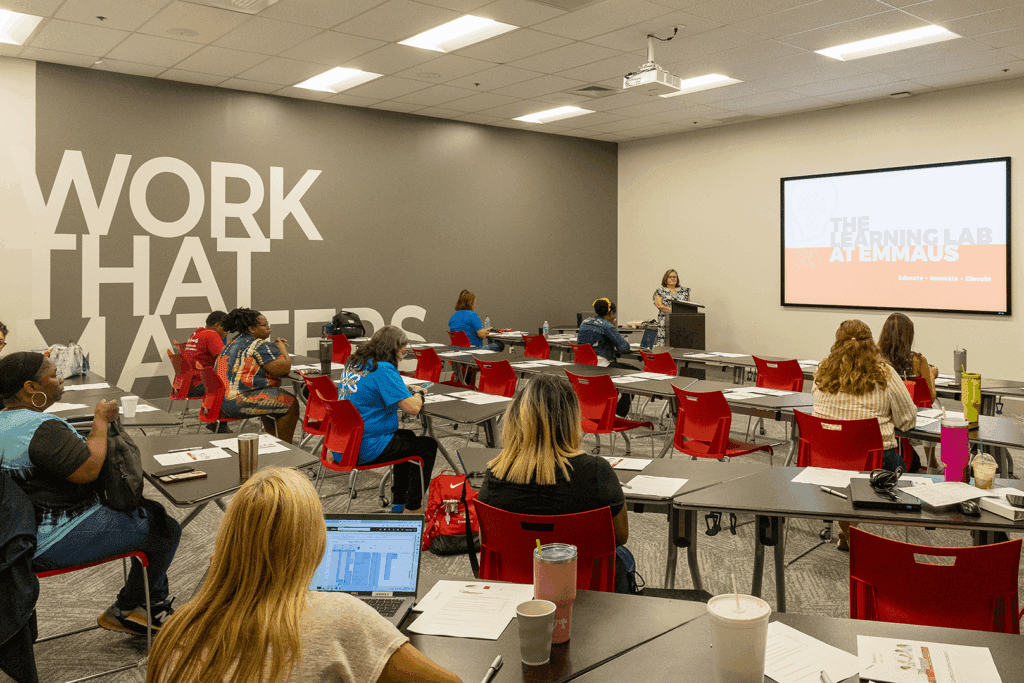

Starting in August 2025, each new hire at Emmaus will complete training in the lab before working independently with clients. They’ll also bring existing staff to the lab for refresher training.

While it will take time to gauge the lab’s long-term impact on injuries or work comp claims, the organization believes it will lead to several improvements:

- Reduction in frequency and severity of injuries

- Improved confidence and preparedness for new employees

Emmaus’s consistent training program in the lab means everyone gets the same quality of training regardless of who conducts it, eliminating the variability that previously contributed to safety concerns.

“It will take years to see the full impact of this change, but we’re excited to see the results,” noted Grosch. “Learning in a real-world environment helps employees be better prepared for the job. Consequently, we’re already seeing a reduction in injury severity.”

Lessons learned and looking to the future

The training lab has implications beyond Emmaus: Soon, they will begin sharing their success by letting others in the community use the facility.

“This is the kind of innovation I want to share with other clients. It’s rooted in real-world safety needs,” remarked Grosch, who said he would recommend this type of training lab to similar policyholders.

At MEM, we’re proud to provide free safety education resources. We’re also grateful for the things we learn from our policyholders. We learned a few valuable lessons from Emmaus’s project:

- Grassroots safety initiatives work. Some of the best safety solutions come from the people doing the work. As an insurance company, we can provide support and resources (like the safety grant that helped fund this project), but the Emmaus team was uniquely able to tailor the idea to their needs.

- Hands-on training beats theory. Practice in a realistic environment prepares employees in a way that classroom or online instruction simply can’t.

- Phased implementation makes big ideas possible. By building the lab over time, Emmaus made an ambitious project manageable.

- Prevention pays off. The upfront cost of building a training lab will be offset by a reduction in work comp claims and higher employee retention.

When it comes to preparing healthcare workers for the physical demands of their jobs, Emmaus has shown that creating a realistic practice environment can make a big difference, in terms of both employee safety and quality of care.

MEM Safety Grant Program

MEM policyholders are eligible for a safety grant, regardless of premium size or claims history. Successful applicants earn one-to-one matching grants of up to $10,000 toward approved safety initiatives. Policyholders are required to monitor claims data and report on the grant’s success so MEM can help other businesses learn from their experience.

“MEM believed in our vision of the training lab from the very beginning,” recalled Stacy Spradling, Chief HR Officer at Emmaus. “To see it go from idea, to being built, to being used for employee training has been incredible. We truly appreciate MEM’s support, through both the safety grant and the ongoing safety consultation that Andrew provides.”

You can read even more safety grant success stories on our blog. Visit our Safety Grants page to learn more about the program and how policyholders can apply.